January 20, 2013 -

Got the NACA duct forward of the forward landing gear bulkhead glued down and sanded down to the dimensions called for and I have the lower corners along the lower longerons trimmed and sanded off to almost completion. the perment lower half of the firewall is installed and flox in and the longerons have been cut off flush with the firewall.

As it turns out I did have enough of the plywood remaining to get the four board to place between the aft landing gear bulkhead and the firewall. And the four small pieces of plywood needed that goes around the landing gear srtut on the fuselage have been installed.

I have ordered a antenna kit from Jim Weir's company RST. Be sure to order it early, I have been waiting for over three weeks on it and still not here.

My biggest concern in the earler part of the construction process was going to be the cutting the lower corners along the longerons. I would of rather had a double root canal. But as it worked out it was not nearly that bad. I just cut at a 45 degree angle down to the wooden longeron, then I used a belt sander it take off enough of the wood to get the 1/4 inch exposed as called for. Then I went back a cut some more foam at the outer edges of the first cut with a hack saw as before. Then I used the sure form, but I always called them a cheese grater. The sure form takes the foam down pretty quickly but you have a lot better idea of how much you are removing as compaired with the saw blade which you are not so sure until the pieces fall off. It might be a bit to late at that time.

|

I have the bottom sides about 80% sanded to it's final form. |

|

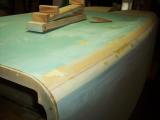

Here is a close up of the front part of the NACA scoop. |

|

|

A close up of the most aft part of the NACA scoop on the fuselage. |

|

|

|

We are using a router to lower the foam around the landing brake cut out. |

|

Some MUST HAVE tools

| Hidden rudder bell horns | Seems to be a cleaner approach. There appears to be plans available from RAF. Slade has link on his site for RAF to get plans. SOLUTION: We made our own hidden horns out of carbon. |

|

|

||